About The Paperworks Group

The other day I had the opportunity to fill in a part of my

artistic education that has been missed up until now. I went to the

Paperworks Inc. studio at the M16 art workspace and gallery in Griffith, Canberra

and learnt how to make paper. For a gold coin donation I received

instruction in how to create a sheet of hand made paper from bits of old

blue jeans.

As someone who

paints with watercolour onto Arches paper made from cloth, and as an amateur printmaker

who likes to print onto handmade paper, I have often wondered how cloth

paper was made, and thanks to some very friendly and helpful papermakers,

I now know the basics.

I have been attending some workshops run by the Artists Society of Canberra in the M16 complex, which is how I found out about this dedicated group of papermakers, who help disabled people and also provide fun classes for the community in general and have a vision of "social inclusion through community art" and a mission of "Bringing people together through recycling, hand print- and papermaking."

The Help They Need

Now that I have

discovered them, I was rather dismayed to learn that due to financial

constraints and a fall in grants, this group is currently seeking for new

premises where they can continue to undertake their work of helping the

community, especially people with disabilities. They require a location

that is inexpensive (free would be better), close to public transport and able

to be accessed by people with disabilities. If anyone in Canberra is

aware of any location that might be a suitable premises please contact them at

their Paperwork Inc. Facebook Page for the present, as

the website appears to be down at the time of writing this blog. They

really need help in finding a place so they can carry on their good work. Interested persons may make donations to Paperworks Inc. Hands Across Canberra.

Getting Down to the Business of Paper Making

Below are some

photos I took of the paper making process.

One pair of blue jeans (must be 100% cotton) makes between 15 and 20

sheets of paper (depending upon the size of the jeans). If any material used is not 100% cotton the

paper making process does not work properly.

One can test a material if its content is not known by burning a little

piece with a match – 100% cotton burns without leaving a residue.

The first step is to cut up the old jeans

into tiny 1cm squares (a rather time consuming exercise). Paperworks is lucky in having a machine that further breaks these squares down into pulp, which save a lot of time and

hard work when you are working with material as tough as denim.

Once the broken down denim is obtained it is

mixed with a small amount of gelatine (and water) to help bind the fibres

better. Denim is such a good material to use that often the gelatine is not even necessary - the fibres bind without it. It is then a simple process of

stirring up the mix (so the bits of pulp are in suspension throughout the fluid) and placing the framed wire mesh boards into the mix, vertically down the sides of the container and then moving them horizontal before lifting them up to the surface. On the way up the wire mesh catches the fibres and the water falls through the mess. Once the water has been allowed to run off

for a minute or two, the mesh boards are tipped over and placed onto some dry

cloth with a board under it. Pressure is

applied to the back of the mess to remove excess water and push the pulp onto

the cloth. After the frame is lifted

away the pulp remains on the surface of the cloth and it is all then left to dry. Once dry it is a simple task to remove the paper from the cloth by simply pulling on and stretching out the drying cloth

causing it to release from the paper, which can then be lifted off (and ironed

if necessary). It was a warm day and my piece of paper was dry on the cloth after being left inside the car for a short while whilst I did some shopping. How easy is that! I have a sheet I made and some that I purchased - can't wait to try printing my lino cuts onto them to see how they look.

|

| The small cut up pieces of denim ready to be placed into the pupling machine. |

|

| The container of water, gelatine and pulped denim. |

|

| The frame with wire mesh and some pulp on its drying cloth. |

Of course, denim isn't the only natural fibre that can be made into paper and at the Paperworks they use all sorts of natural materials. I had notice about 2 weeks before, when I looked out the window at M16, a group of people were busily doing something with what looked like tulip leaves and I wondered if someone had made a clandestine raid at Canberra's Floriade. As I later found out, tulip leaves make very good paper and the Paperworks members had been lucky enough to be given some of Floriade's waste foliage to use for paper making, with the result that one of the member's garage now looks like this photo:

| ||||

| Tulip stems and leaves drying in preparation for paper making. |

You can read more about making paper from Floriade's tulips on their Paperworks Inc. Facebook Page.

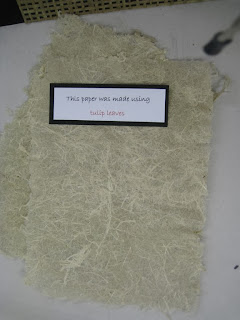

The group had set out an interesting display featuring different types of paper and showing what the pulp for each type looked like.

Other types featured included paper made from items such as corn, flax and Ginkgo Biloba. It was interesting to note the difference in appearance based on what was the main ingredient:

| |||||

| Paper made from tulip leaves. |

|

| Cotton, Ginkgo Biloba and Flax |

|

| Corn, Ginkgo Biloba and a small amount of Cotton |

|

| Corn, Flax and Gingko Biloba |

|

| Denim, Flax and Gingko Biloba |

Examples of different pulps:

Paperworks make a number of lovely gift items, which are sold at locations around Canberra. Below are some examples of items produced by them and by the Friday morning workgroup.

Overall, I thoroughly enjoyed my visit to Paperworks Inc. and I can really see how it would be easy to become addicted to papermaking. Even though sometimes there is a bit of work involved it seems well worth it when you look at some of the lovely items that can be made using the beautifully textured sheets. One of these days (time and money permitting) I reckon I might just buy a papermaking kit and have a bit more of a play.

The making of the tulip paper is now well under way and it will be available soon. For further information check their Paperworks Inc. Facebook page. By the way, denim jeans are always needed, so if you have any old jeans (100% cotton only) they would be happy to have them.

Cheers.

No comments:

Post a Comment